Wind Energy

With an extensive two decades of experience serving the wind energy sector, Aegis Rubber Engineering stands at the forefront of manufacturing high-quality components tailored to a diverse range of turbine designs and capacities, ranging from 250kW to 5MW and beyond.

Our specialised offerings encompass a spectrum of components crucial for wind turbine functionality, including:

- Gearbox Bushes

- Generator Mounts

- Direct-Drive Torque Reactors

- Nacelle Hood Mounts

- Coupling Bushes

- Yaw Bearings

At Aegis Rubber Engineering, we can provide you with the expertise to manufacture parts that precisely meet specific stiffness requirements, ensuring optimal performance in varied wind conditions. Notably, our supplied components have demonstrated exceptional durability, with some parts remaining in service for over fifteen years - a testament to the reliability and longevity of our products.

In our commitment to sustainability within the renewable energy sector, we complement new product manufacturing by offering a comprehensive refurbishment service for parts removed during maintenance cycles. This service not only ensures the recovery and re-use of metal components where possible but also reflects our dedication to extending the life cycle of wind energy components, contributing to a more sustainable future.

Explore our history in wind energy solutions and discover how Aegis Rubber Engineering continues to drive innovation and reliability in this dynamic industry.

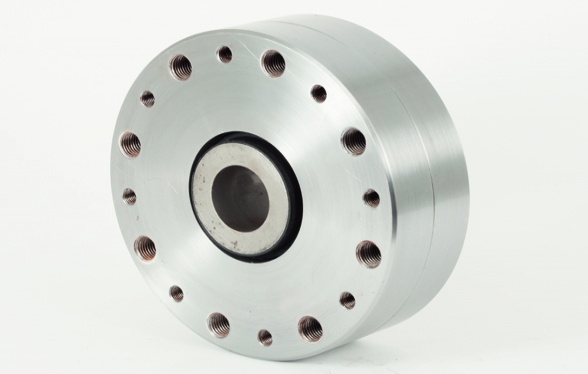

Bonded bushes

View

The fully bonded bush consists of rubber bonded between two concentric steel sleeves. The bush is designed to accommodate small torsion, conical and axial movements and endure radial loads.

Duplex Bushes

View

Duplex bushes are similar to standard bushes, but are reinforced with an intermediate tube. This bush configuration provides high radial load bearing whilst retaining low axial and torsional stiffness rates.

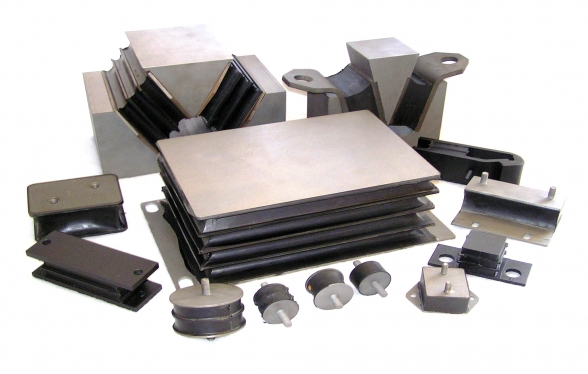

Sandwich, bobbin and shear mounts are used for a variety of applications including engine mounts and vibration equipment. They are designed to accommodate misalignment and provide vibration and shock isolation for shear and compressive axial loads.

A semi-bonded bush consists of rubber sandwiched between two concentric steel sleeves. The rubber is bonded to the inner sleeve and interference fitted to the outer sleeve. The semi-bonded bush is designed to accommodate small torsion, conical and axial movements and endure radial loads.