16th May 2023

Aegis Rubber Engineering has been a trusted supplier of OEM parts to the wind energy sector for many years.

Understanding the importance of wind energy and wind power:

Wind energy is a crucial component in the transition towards a cleaner and more sustainable energy system. As a renewable energy source, wind power has the potential to significantly reduce carbon emissions and mitigate the negative impacts of climate change. Additionally, wind energy has become increasingly cost-competitive, making it an attractive option for power generation in many parts of the world.

Background to the project

As part of the wind industry's regular maintenance and refit programmes, wind turbines require part replacement at the end of their service life. Aegis provides both new and refurbished parts to support the wind energy maintenance industry, ensuring that wind farms continue to operate at peak performance.

Project requirements

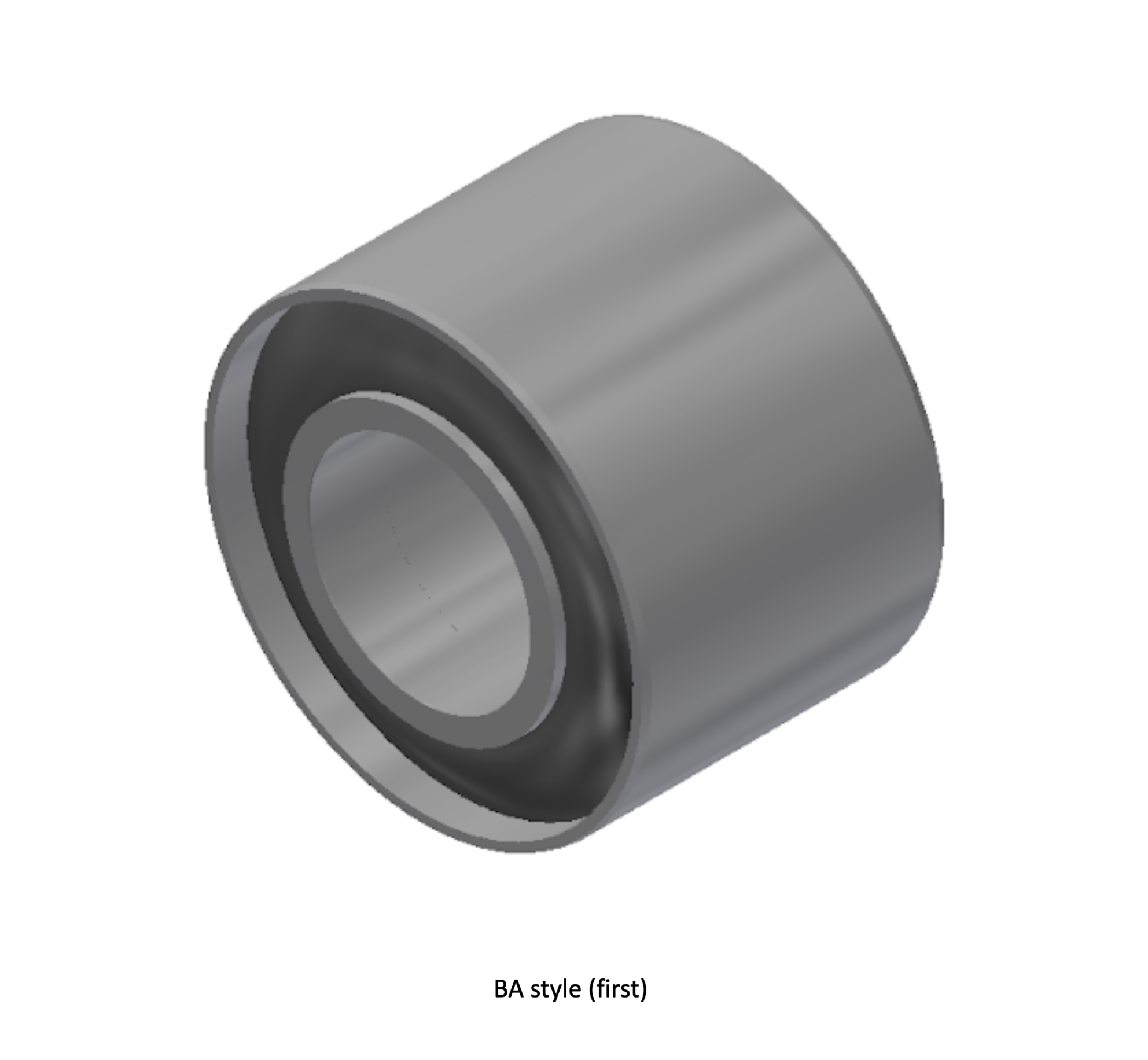

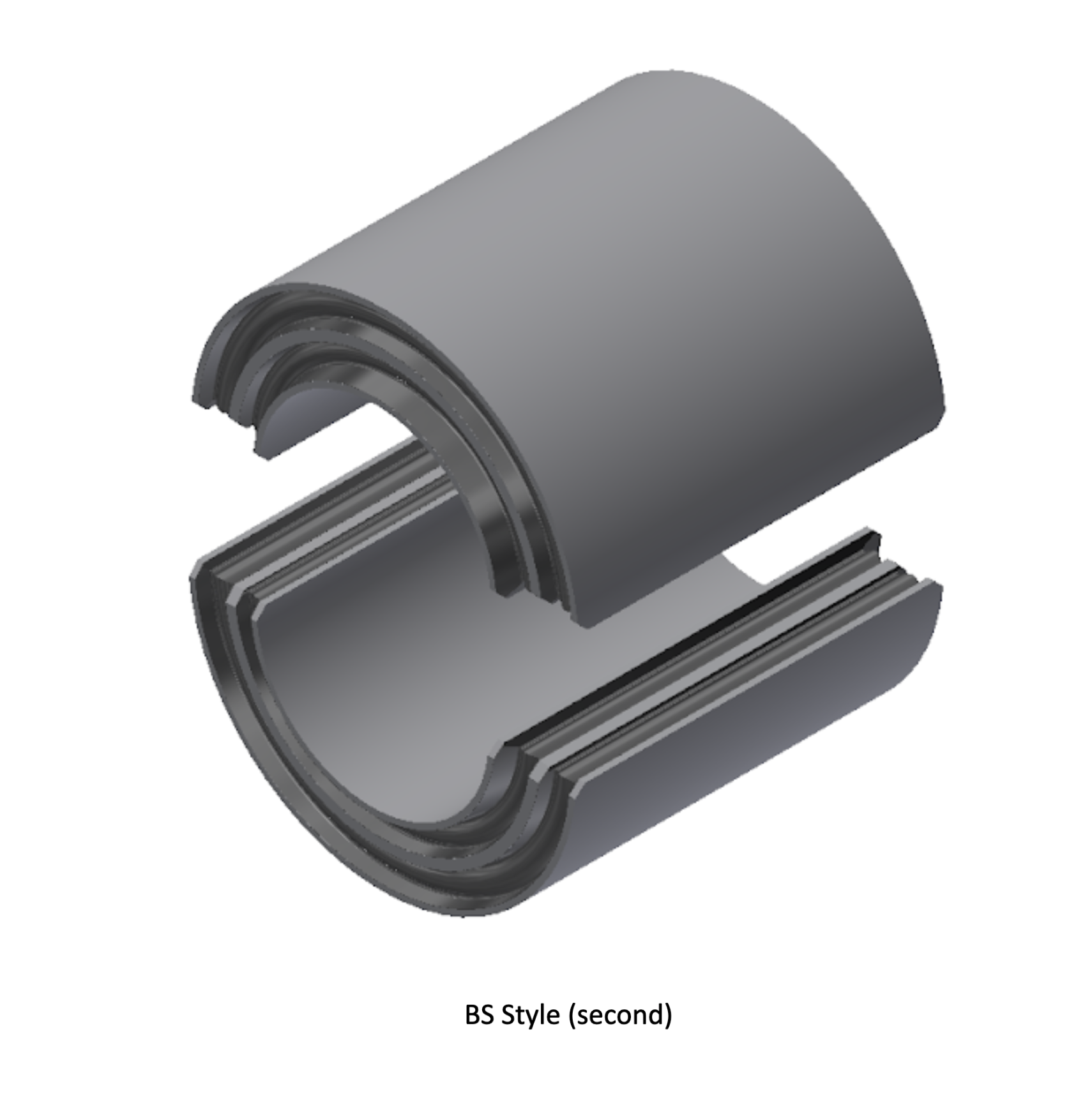

A wind energy customer approached us with a problem during their regular turbine maintenance programme. They were having difficulty fitting an existing part, which was originally designed as a split bush. This means that the component comes in two half shells that need to be joined together. Despite the challenge, they were looking for a similar design to a split bush as it offers slightly higher load-bearing capacity compared to the concentric single-piece bush design, thanks to its additional rubber layer. Moreover, the two layers of metal ensure that the stiffness is comparable.

The challenges of wind turbine maintenance

Installing the split bush on site required it to be placed in a closed gear stay, but the customer was having trouble correctly fitting the two component halves together.

Objectives of creating a new part

Aegis Rubber Engineering worked closely with the customer to design a solution that would meet their specific requirements. The customer required a part that could be easily installed, yet possess the same load-bearing capacity as the split design. Additionally, they wanted the part to offer the longer service life that the split design provides over the conventional concentric bush design.

Our effective solutions for wind turbine maintenance in the wind energy industry

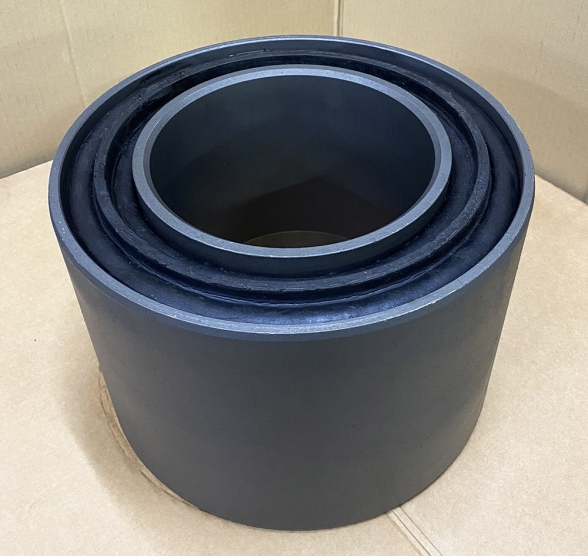

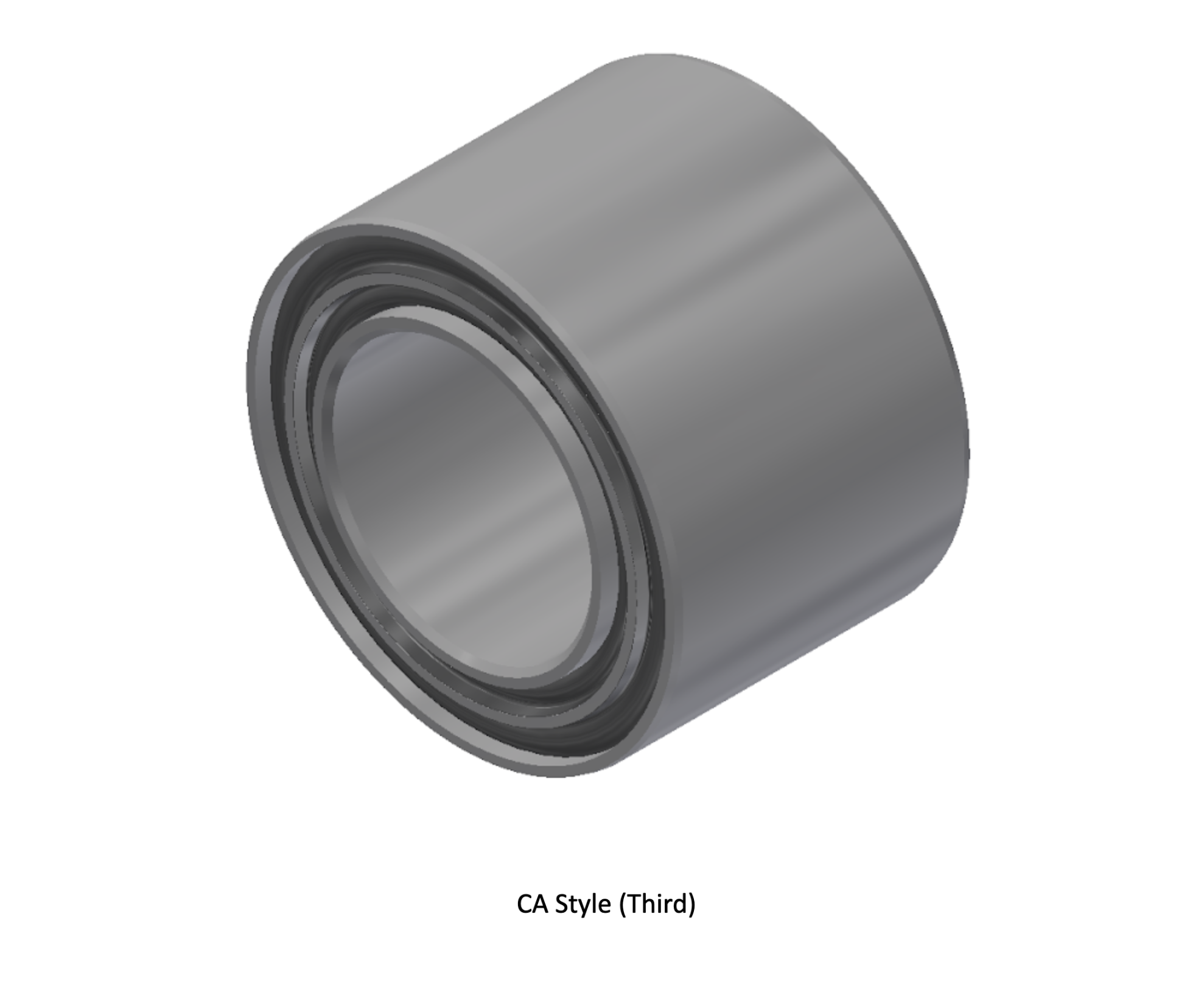

Our team of experienced engineers designed a new part that met the customer’s specification. The new part featured an additional metal interleaf between the inner and outer race, which ensured the stiffness was roughly the same as the split design. This duplex design maintained the single-component style required for easier installation, solving the customer's installation issue.

Additionally, the new design allowed the customer to reuse existing torque arms in their maintenance cycle, as it could be installed more easily within the gear stay.

The newly developed duplex part underwent in-house testing to ensure that it complied with the customer's specifications.

The new part provided higher load-bearing capability and longer service life, ensuring the wind farm continues to operate at peak performance.

Aegis Rubber Engineering continues to supply high-quality OEM parts to the wind energy sector, ensuring that wind turbines operate efficiently and effectively. Our experienced team of engineers work closely with our customers to understand their specific requirements, ensuring that we provide solutions that meet their needs.

Contact us today to learn how we can help with your wind energy maintenance needs.